Product Description

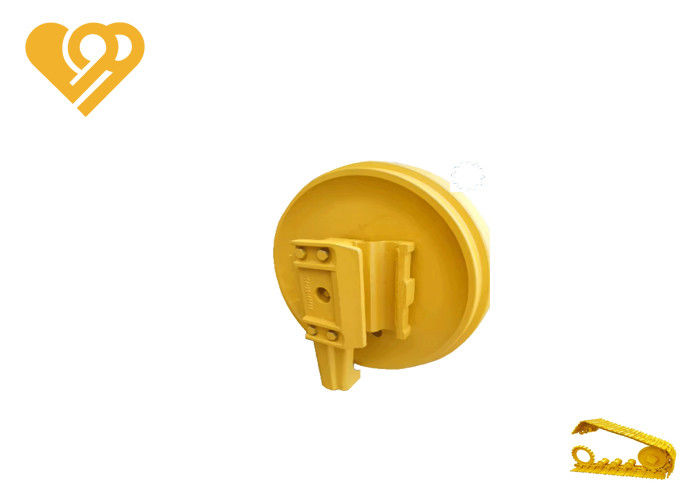

Front Idler Assembly for OEM Excavator Undercarriage Parts

1. What is idler?

The keyed joint between the idler wheel and the drive shaft offers an expanded bearing surface and enhanced transmission of torque, which boosts dependability and synchronizes the service life of the idler with other components of the undercarriage. The motion of the drive shaft within fixed bearings results in decreased friction and stress. An extended service life of the track system leads to fewer replacement cycles, thereby minimizing the workers' exposure to potential hazards.

2. Idler Characteristic

* A genuine Front Idler

- Decreases the stress on bearings by 50% to reduce the load on bearings and prolong the lifespan of components.

- Sturdy rock shields defend against harm from soil and rubble.

- Contributes to the reduction of mining operational expenses by prolonging the life of the track system and reducing unexpected stoppages.

- Enhances track performance by expanding the bearing surface and the distribution of lubrication.

* Increased Productivity

- Splined connection between idler and shaft increases reliability and matches idler life with that of other lower works components

- Bearing blocks with bushings can be removed without breaking the track

- Dedied lube injectors supply lubricant to critical wear surfaces

* Lower Total Cost Of Ownership

- 50% less bearing stress reduces bearing loads and increases component life

- Rotating shaft within stationary bushings produces less contact stress and wear

- Heavy-duty rock guard prevents dirt and debris from damaging parts

* Enhanced Safety

- Longer crawler system life increases change-out intervals reducing employee exposure to safety risks from system change-outs and component replacement

3. Main Dimensions of Installation

Main Parameters

| Brand |

Model |

Main Dimensions of Installation |

Remarks |

| A |

B |

D |

L |

M |

N |

O |

| |

E307 |

440 |

407 |

100 |

236 |

176 |

40 |

50 |

|

| E100B |

480 |

450 |

130 |

270 |

216 |

46 |

60 |

|

| E120B |

480 |

450 |

130 |

270 |

216 |

46 |

60 |

|

| E200B |

540 |

500 |

160 |

300 |

270 |

60 |

65 |

|

| E215 |

480 |

450 |

130 |

270 |

216 |

46 |

60 |

|

| E312 |

480 |

450 |

130 |

270 |

216 |

46 |

60 |

|

| E320 |

540 |

500 |

160 |

300 |

270 |

60 |

65 |

|

| E330 |

680 |

636 |

214 |

373 |

350 |

60 |

85 |

|

The Models Above Are Just For Reference, Many Models We Can't List Here. We Can Supply More Products As Your Requirement. Please Feel Free To Send Us Your Inquiry Or Email If You Have Any Requirements.

4. Our Advantages

* World-class quality

* Factory sale directly with reasonable price

* 35 years' experience in Excavator & Bulldozer spare parts manufacturing

* Flexible payment terms including T/T, L/C and so on

* Fast delivery within 30 days after contract established

* Professional sales team, quality inspection and report, maritime logistics guidance

* After-sale services: video technical support, 24h online support

5. Hot Sale Parts

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!