Product Description

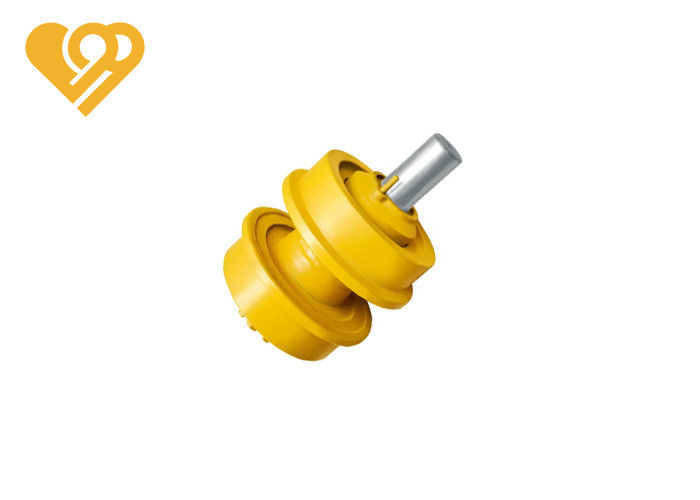

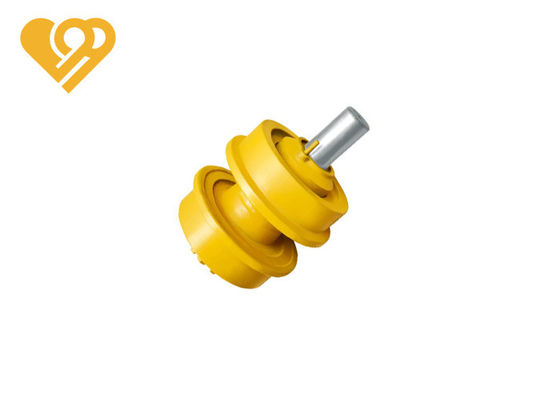

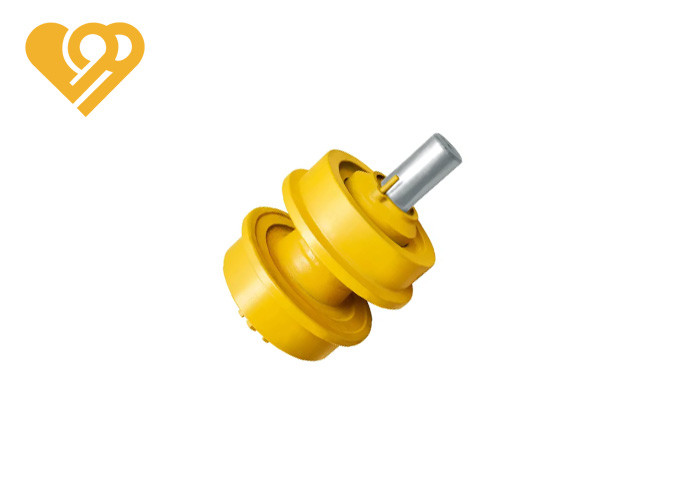

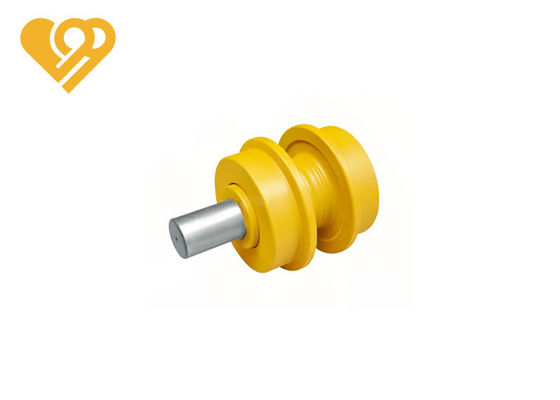

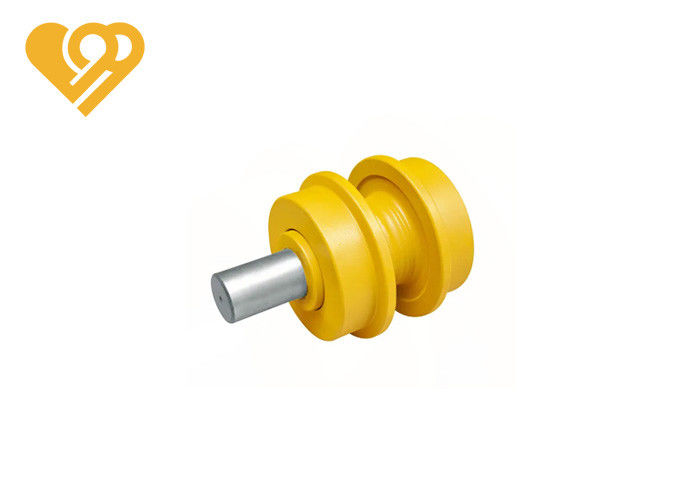

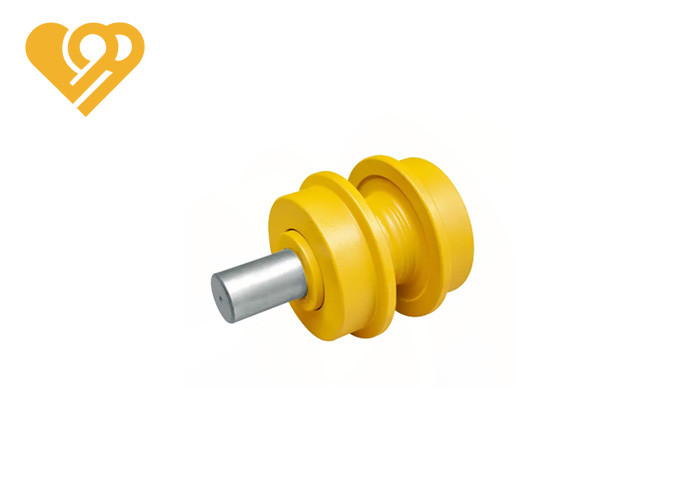

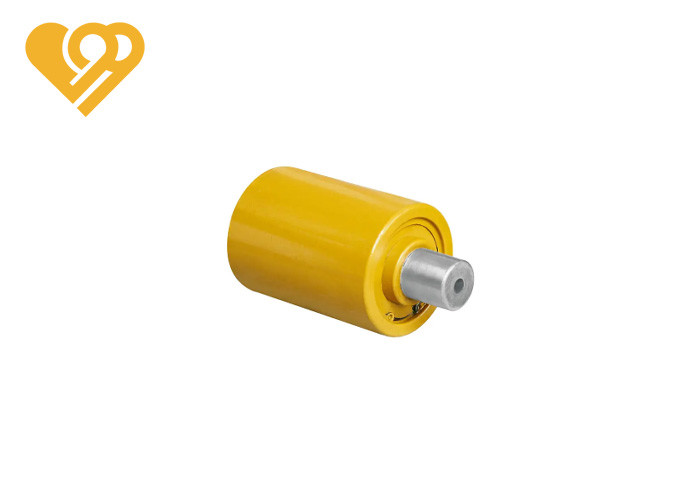

High Duty Forged Steel Carrier Roller For Ex200 Ex220 Ex240 Ex300 - Hitachi Excavator Undercarriage Spare Parts

In construction and mining, downtime can lead to big financial losses. If your EX200/220/240/300 excavator's track system is wearing prematurely, misaligned, or malfunctioning frequently, consider upgrading. Our OEM-grade Carroer roller Replacement is designed for heavy-duty operations to ensure optimal performance. As a trusted direct factory supplier, we offer superior quality components at competitive prices.

1. What is a roller?

The roller, which is an important part of the belt conveyor, has many kinds and large quantities, and can support the conveyor belt and the weight of the material. It accounts for 35% of the total cost of a belt conveyor, which produces more than 70% resistance, so the quality of the roller is particularly important. It has two kinds of steel and plastic.

The materials available for Track roller and Carrier roller are 40Mn2,40MnB,50Mn. depending on working conditions. The rollers are normalized with precision forging before overall heat treatment to achieve surface hardness of HRC52-6 and the depth of hardened layer reaches more than 7-10mm (HRC45), This ensures higher durability with high impact resistance and surface wear resistance on the contact surface of the rollers. High quality floating seals and lubricating system are used to adapt to different climate and temperature The track and carrier rollers is able to work under severe working conditions or climate ranging from-45℃~120℃, keeping the components free from maintenance.

Forged for the Toughest Conditions

Carrier roller are meticulously crafted using high-strength alloy steel and advanced hot-forging techniques, ensuring unparalleled durability and longevity. These Carrier rollers are designed with robustness in mind, capable of withstanding extreme loads and impacts. This makes them the perfect choice for challenging construction and mining applications. No matter the environment, whether navigating through rocky terrain or plowing through dense soil, these Carrier rollers consistently deliver reliable performance in the harshest of conditions.

Precision Engineering for Optimal Functionality

Carrier roller are subjected to a rigorous design process, with a paramount emphasis on precision to achieve an optimal structure that ensures flawless track alignment. This innovative design dramatically reduces friction and wear, thereby extending the lifespan of your undercarriage components by an impressive 40%, in comparison to traditional standard models. The benefits are clear: fewer replacements are necessitated, resulting in diminished maintenance costs and enhanced productivity at your worksite.

User-Friendly Maintenance

Carrier roller are subjected to a rigorous design process, with a paramount emphasis on precision to achieve an optimal structure that ensures flawless track alignment. This advanced design dramatically reduces friction and wear, thereby extending the lifespan of your undercarriage components by an impressive 40% in comparison to traditional standard models. The benefits are clear: fewer replacements are necessitated, resulting in lower maintenance costs and enhanced productivity at your worksite.

✅ OEM-Quality Assurance: Carrier not only meet but often exceed Hitachi’s original specifications, guaranteeing seamless compatibility and optimal performance.

✅ Significant Cost Savings: By eliminating distributor markups, we are able to offer savings of up to 30% when compared to traditional supply channels. This cost-effective approach helps you maintain control over your project budget, ensuring that your financial resources are utilized in the most efficient manner possible.

✅ Swift Global Delivery: We know you can’t afford to wait. That’s why we offer fast shipping, with orders dispatched within 25 days to locations worldwide.

✅ Comprehensive Support: Our team of experts provides 24/7 technical assistance, and every idler comes with a 12-month warranty, giving you peace of mind with your purchase.

4. Main Dimensions of Installation

5. Detecting Equipments

6. Hot Sale Products

7. Our Advantages

-

World-class quality

-

Factory sale directly with reasonable price

-

Flexible payment terms including T/T,L/C and so on

-

Fast delivery within 30 days after contract established

-

After-sale services: video technical support, 24h online support

Are you still plagued by the absence of a top-quality excavator idler? Look no further than YinTai Parts, a leading manufacturer and supplier of excavator idlers in China. We boast an array of high-quality products available for purchase. With over three decades of experience and extensive expertise in the field, we guarantee the superior quality and exceptional performance of our products, ensuring your satisfaction.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!