Product Description

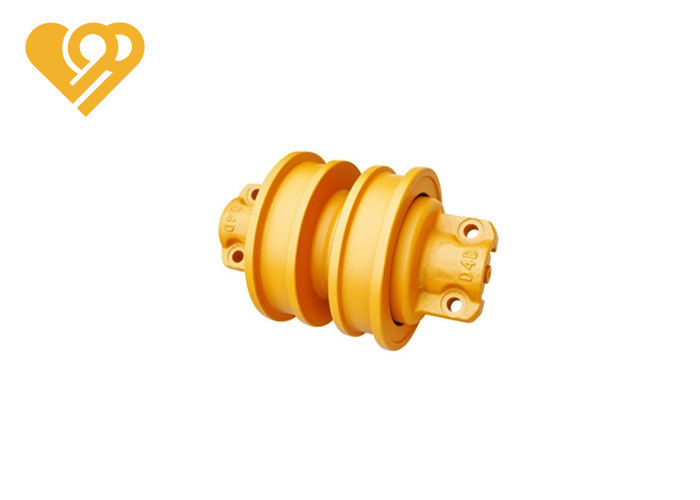

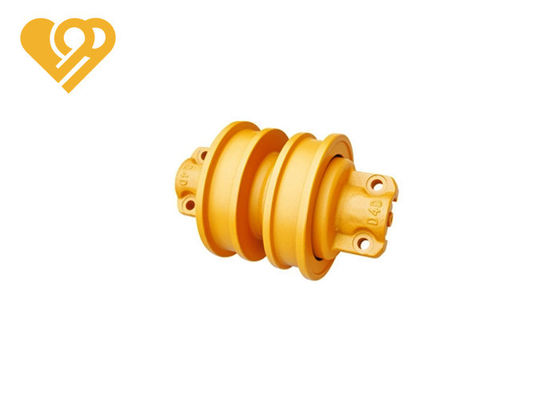

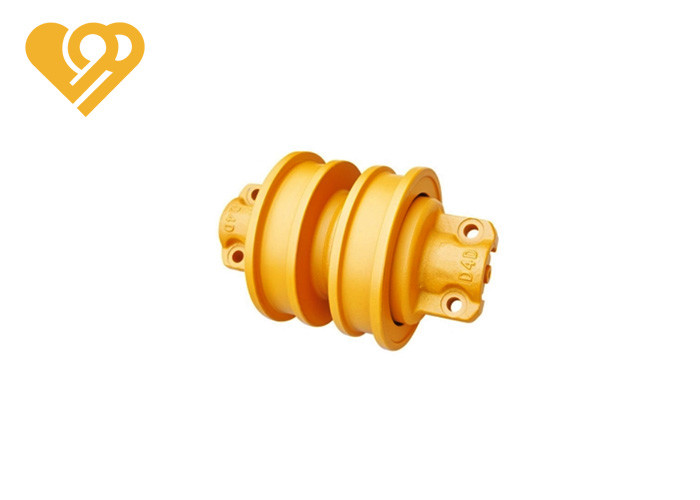

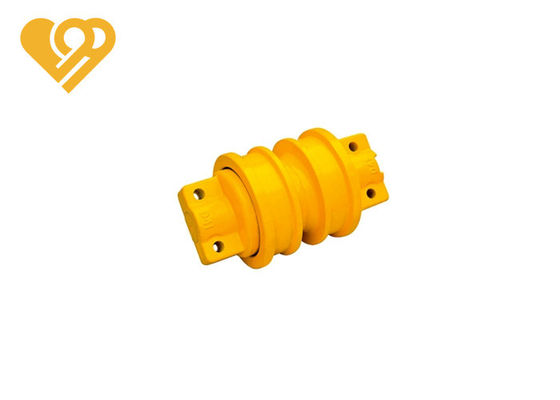

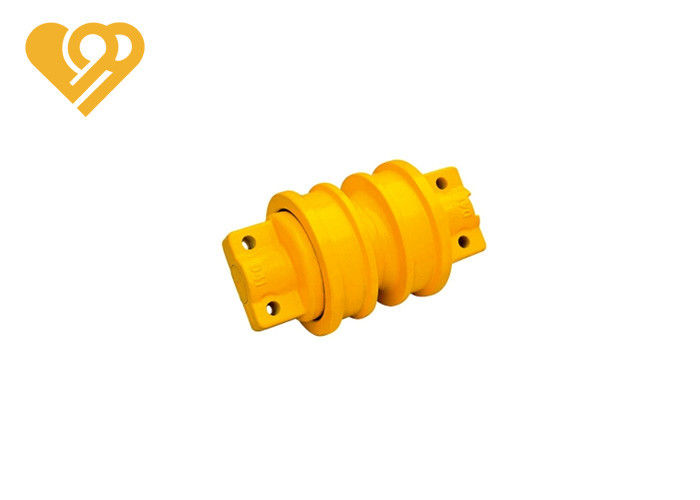

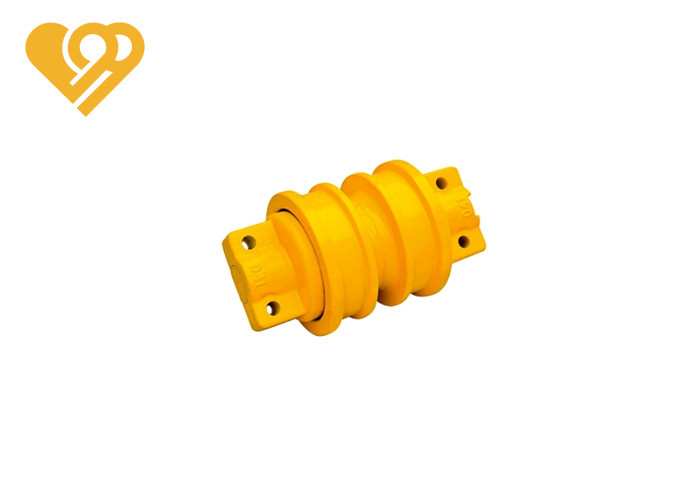

Caterpillar OEM Quality Undercarriage Spare Parts For D4H D4D D4E Double Flanges Track Rollers for Bulldozer and Harvester

1. What is a track roller?

As the critical load-bearing core of excavator undercarriages, track rollers bear the machine’s full weight, withstand severe ground impacts, and generate over 70% of total operational resistance. Each roller is subjected to high-pressure gas testing at 0.6 MPa (6 bar) – 60% above industry norms – to guarantee reliability in extreme operating environments. This critical QC measure prevents potential oil leaks at the source, resulting in assemblies validated for >10,000-hour lifespans despite persistent immersion in high-abrasion media like mud and sand.

2. Engineering Excellence: Why Our Track Rollers Dominate Severe Conditions

✅ Military-Grade Sealing Integrity

Each roller is subjected to high-pressure gas testing at 0.6 MPa (6 bar) – 60% above industry norms – to guarantee reliability in extreme operating environments. This critical QC measure prevents potential oil leaks at the source, resulting in assemblies validated for >10,000-hour lifespans despite persistent immersion in high-abrasion media like mud and sand.

✅ Forged Alloy Armor Defense

Precision-forged shells undergo specialized deep-case hardening followed by quench-tempering treatments, creating an optimal balance of surface resilience and structural integrity. This controlled thermal processing achieves critical performance benchmarks: a Rockwell 60-65 HRC surface hardness for extreme wear resistance, 450MPa+ tensile strength to withstand high-impact loads, and triple-layer chrome plating on shafts that combats corrosion while minimizing friction. Together, these properties deliver exceptional durability in abrasive operating environments.

✅ Battle-Proven Load Capacity

Our re-engineered internal raceways and optimized tapered bearings achieve 30% more efficient load force distribution. This advanced geometry prevents two critical failure modes: premature flange wear caused by localized stress concentrations, and bending deformation during high-cycle fatigue operations. By eliminating these failure points, the system maintains structural integrity under sustained cyclical loading – extending service life and reducing unplanned downtime.

3. The Cost-Smart Solution for Mining & Heavy Earthmoving

Conquer Rocky Terrain & Slash Costs on Your D3C

Tired of your D3C suffering from:

- Premature roller failure on harsh, rocky ground?

- Spiraling maintenance bills as hours climb?

- Profit-killing unplanned downtime?

Upgrade to Our D3C Rollers for Proven Results & ROI:

- ✅ Save 22% on Fuel: Advanced design delivers significantly lower rolling resistance.

- ✅ Perfect Komatsu Fit: Direct interchange with 70G-75-21100 rollers - installs seamlessly.

- ✅ Unmatched Durability: Built tough with premium alloys, backed by a robust 3-Year Structural Warranty.

Unstoppable Traction & Uptime Start Here:

Factory-Direct Pricing | ISO 9001 Certified Quality | Global Logistics Network

4. Production Processes

5. Track Roller Structure

6. Design/Structure/Main Dimensions of Installation

7. Our Advantages

* World-class quality

* Factory sale directly with reasonable price

* 35 years experience in Excavator & Bulldozer spare parts manufacturing

* Flexible payment terms including T/T, L/C and so on

* Fast delivery within 30 days after contract established

* Professional sales team, quality inspection, and report, maritime logistics guidance

* After-sale services: video technical support,24h online support

8. Hot Sale Products

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!